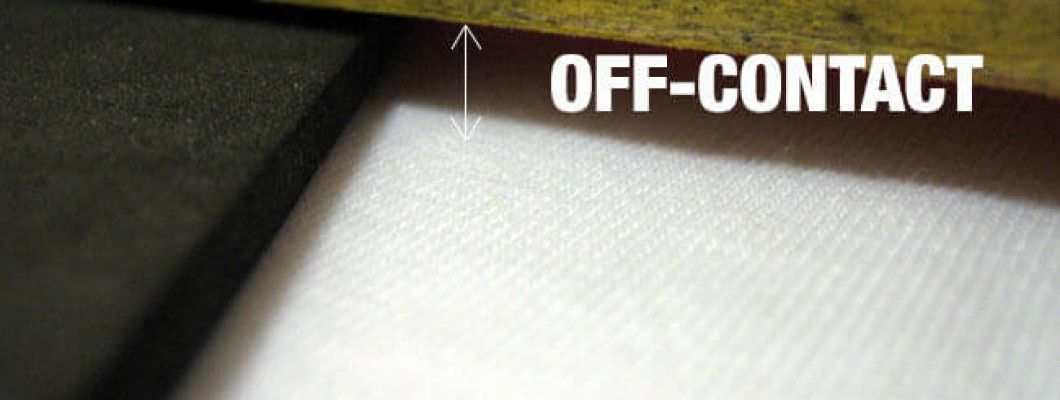

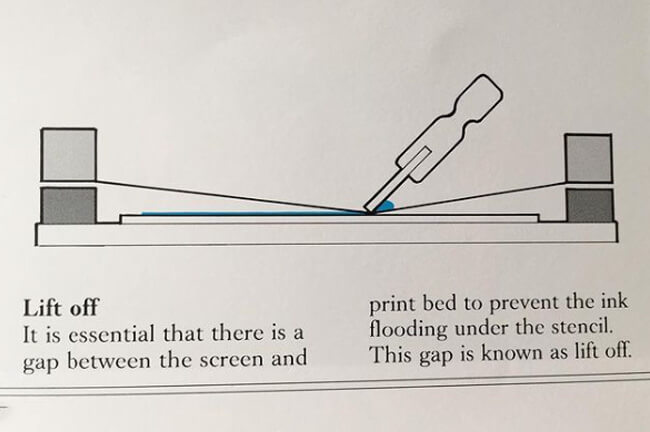

The off-contact is the distance between the screen printing frame and the printing substrate when the squeegee passes to deposit ink. This separation is essential for obtaining sharp and consistent prints.

How It Works

During printing:

- The frame is raised 1-5mm from the substrate (off-contact)

- The squeegee, pressing the ink, momentarily brings the mesh into contact with the material

- The frame returns to its original position after the pass

Why is Off-Contact Important?

Proper adjustment directly affects:

| Parameter | Effect |

|---|---|

| Sharpness | Prevents smudging and double impressions |

| Consistency | Ensures even ink distribution |

| Frame Longevity | Reduces wear on mesh and emulsion |

| Clean Release | Allows the frame to lift without dragging ink |

Expert Says:

"Without off-contact, the mesh would stick to the substrate causing smeared prints and difficult release" - Marco Rossi, professional printer

How to Adjust Off-Contact

The optimal setting depends on:

- Material being printed

- Mesh tension

- Frame size

- Ink type

Adjustment Method

- Initial measurement: Use feeler gauges or spacers

- 3-5mm for fabrics

- 1.5-3mm for paper/cardboard

- 0.5-2mm for plastic/metal

- Test prints: Run tests with different distances

- Fine adjustment: Modify gradually (0.5mm at a time)

Common Problems and Solutions

1. Smudging and Double Impressions

Cause: Insufficient off-contact

Solution: Increase distance by 1mm and check mesh tension

2. Incomplete Ink Coverage

Cause: Excessive off-contact

Solution: Gradually reduce distance

3. Difficult Release

Cause: Over-tensioned mesh or incorrect squeegee angle

Solution: Adjust to 75° angle and verify tension

Warning!

Improper off-contact can cause "ghosting" (image shadowing) in subsequent prints.

VIDEO TUTORIAL

Practical Adjustment Examples

Example 1: Cotton T-Shirts

- Frame: 55T - 20N/cm tension

- Ink: Plastisol

- Ideal off-contact: 3mm

- Problem solved: Eliminated edge bleeding

Example 2: Thick Paper Posters

- Frame: 100T - 25N/cm tension

- Ink: Water-based

- Ideal off-contact: 1.5mm

- Problem solved: Improved ink adhesion

Example 3: PVC Panels

- Frame: 77T (195 mesh), 18N/cm tension

- Ink: UV

- Ideal off-contact: 0.7mm

- Problem solved: Enhanced fine detail reproduction

Conclusion

Off-contact is a fundamental parameter that separates amateur prints from professional results. Experimenting with different settings and keeping records of optimal configurations for each frame/ink/material combination is key to consistent results. Remember: small adjustments can make a big difference!

Leave a Comment